Two-Tier ERP – Because One Size Does Not Fit All

AT A GLANCE

- What is two-tier ERP?

- Why should you consider two-tier ERP as a strategy?

- When does a two-tier ERP strategy make sense?

- Why should you consider Oracle for your two-tier solution?

WHAT IS TWO-TIER ERP?

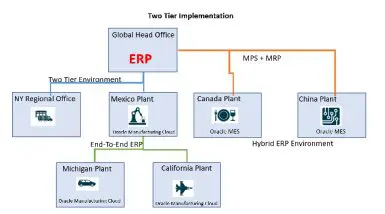

Two-tire Enterprise Resource Planning (ERP) is an increasingly common term used to describe how a multi-entity company maintains a legacy ERP system to manage the business operations and financials of the corporations at its headquarters (1st tier) but uses different ERP system (s) (2nd tier) at satellite and roll up consolidate financial and operational data to the corporate ERP backbone. In this scenario, the corporate ERP systems are typically installed at the corporate IT facility (known as on premises), cloud-based Software as a Service (SaaS) solutions are being considered for the 2nd tire ERP.

WHY DO YOU NEED A TWO-TIER ERP STRATEGY

The answer to this question is simply that “one size does not fit all.” Increasingly, the traditional ERP solutions have outgrown the needs of smaller business entities. The legacy systems may be the right tool for coordinating large corporations but have not delivered on customers’ changing business requirements. For many IT decision-makers, the high maintenance costs of traditional ERP have not delivered equivalent value and have led them to seek more innovative solutions to their changing business needs. This innovation comes in the form of a two-tier strategy aimed at providing targeted solutions for manufacturing operations that increase operational efficiencies while reducing the overall IT investment risk.

According to Constellation Research1, there has been increasing interest in two-tier ERP with 48 percent of respondents to a 2011 survey indicating that they are considering two-tier ERP – up 27 percent from the same survey in 2009. In addition to the sentiment that legacy top-tier ERP systems are too rigid for divisional needs, costs were cited as the key objection to a “Single Instance ERP” strategy.

TARGETED SOLUTIONS

The needs required for a high-end production facility can be significantly different than other forms of business, creating a significant challenge for most enterprise systems to satisfy all scenarios. These challenges come in the form of unique requirements like supply chain management, production analytics, product genealogy and quality management. Such manufacturing facilities gain higher operational visibility into their production and supply chain operations by leveraging a targeted solution at the divisional level.

INCREASED OPERATIONAL EFFICIENCIES

Second tier solutions can be a significant advantage, increasing operational efficiency at the satellite location while providing improved visibility from corporate. Cloud ERP solutions are typically more flexible to the needs of smaller organizations and can be deployed much quicker with little or no disruption to the operating business. Significantly lower capital outlays and reduced IT burden make cloud an ideal choice for the 2nd tier ERP. Gartner finds that “the ERP suite is being deconstructed into ‘postmodern ERP.’ This will result in a more federated, loosely coupled ERP environment with much (or perhaps even all) of the functionality sourced as cloud services or via business process outsourcers.” Moreover, they predict “within five years, hybrid ERP environments will be the norm.”2

These benefits do not end at the second tier; the advantages at the corporate parent can be significant as well. Rather than investing in upgrades or customizations to their corporate system that are often required to support the specific needs of the satellites, they can focus their IT budget and resources at optimizing the “right tool for the right job” at corporate, supporting the satellites’ desire to do the same thing with tools better suited to their specific needs.

AGILITY WITH REDUCED INVESTMENT RISK

Now that companies are recovering from the “Great Recession” and are experiencing significant growth for the first time in a decade, they need greater agility with lower risk to expand their business. Expectations from business leaders often include acquisitions (or divestitures) that take on new geographies and/or different lines of business. For example, the expansion into the BRICS countries (Brazil, Russia, India, China and South Africa) creates tremendous opportunities for low cost resources and labor; however, this expansion can stress the typical IT infrastructure and small IT teams at satellite organizations. Upgrading the ERP systems – typically smaller, purpose built or even home grown systems – of the acquired company is just too expensive and disruptive to the incoming organization. One way to reduce the investment risk during such acquisitions is to implement a 2nd tier solution that is a more appropriate fit for the operational requirements of the satellite.

In addition, implementing large, legacy ERP systems at the divisional level is often cost prohibitive when compared to smaller, more nimble 2nd tier solutions, especially cloud-based solutions. In the case of on-premises implementations, license costs and ongoing annual maintenance (typically > 20 percent of the license fees), high-end servers and the skilled IT staff to manage it all creates a wall that many divisional leaders do not want to climb. Finally, expensive and lengthy implementation cycles that may take 6-12 months do not fit the needs of organizations that are facing challenging market conditions and higher expectations from their customers.

WHEN DOES A TWO-TIER STRATEGY MAKES SENSE

There are any number of scenarios where two-tier ERP is the right fit, such as when the legacy top-tier system is operating fine but satellites need attention. The corporation may already have significant investment in ERP and would prefer to continue to optimize it with minimal disruption to the core business. However, at the satellite organizations, the maintenance contracts may be expiring or the versions are so outdated that they must be upgraded to stay operational. Another common scenario is a heavily customized system that requires too much manual maintenance and may have outgrown its useful life. Addressing the cost and effort to upgrade an individual plant to solve its unique needs may make the most sense versus installing an instance of the big top-tier system.

As mentioned earlier, the individual demands at multiple locations may be driving different requirements at the satellite organizations. For example, when acquiring a new subsidiary, it may be easier to satisfy regulatory requirements in its local country. A common scenario is that the acquired satellite has grown through acquisition itself and is already dealing with multiple ERP systems.

Rather than deal with the upgrades, integrations and business disruption of consolidating its own systems – or integrating into the parent’s – it may be a lower risk proposition to move to a cloud based ERP solution that delivers a higher ROI and quicker time to value. This helps companies with standardization across the enterprise and enables more strategic decision making across production facilities.

Similarly, when spinning up a new satellite operation to meet a growing business need, implementing a cloud ERP system can reduce the financial risk to the new entity and perhaps even make them more attractive as a spin-off or for sale. “Next-shoring”, a new trend that actually plans for a finite life for a plant (depending on continued market conditions), benefits from this lower risk scenario and can be shut down if required without having to write down the capital expenses of computer hardware and software licenses (that may not be portable). Rather than implementing an unwieldy instance of the parent’s legacy ERP system, they can gain business advantage with a tool better suited for their specific needs and budget sensitivities.

There are many examples where “one size does not fit all” such as the specific needs required for compliance in different industries or geographies. Each country, industry and business-type combination may create a scenario that no one system could possibly satisfy and requires a custom configuration.

As has already been noted, the top-tier systems are too rigid and do not have the flexibility required for agile companies. Cloud ERP solutions, on the other hand, can be highly flexible and configurable in terms of capabilities, industry support and especially implementation. With a smart SaaS integration strategy, each satellite can have its own configuration “in the cloud” up and running in months and can roll up the necessary data to corporate without a hitch.

“While today’s two-tier strategies mostly involve on-premises solutions, cloudbased solutions will gain favor over the next 18 to 24 months because of their rapid deployment capabilities, constant innovation qualities and subscription pricing. Whether SaaS, on-premises or hybrid, a two-tier ERP strategy will reduce costs, meet new business requirements and provide better business value.” Ray Wang, Constellation Research, “The Case for Two-Tier ERP Deployments”

Finally, although few companies are looking to replace their large, expensive and potentially customized corporate ERP implementations, the rapid innovation being delivered by 2nd tier ERP providers is influencing companies to consider piloting them at a divisional level, then replicating to other divisions. With the flexibility of cloud ERP, this can help to bring up the efficiency and productivity of the whole company without upsetting the corporate ERP “applecart”.

WHY ORACLE FOR YOUR TWO-TIER STRATEGY

Oracle is a cloud-only ERP solution designed specifically for manufacturers with customers and facilities all over the world. Oracle Systems has demonstrated success at delivering end-to-end ERP needs at the manufacturing plant level, and many Oracle customers have replicated their success to multiple plants.

Cloud-based and SaaS solutions provide the best ROI for two-tier deployments and modern web services make implementation much quicker and easier. In the Edge example above, the New York office, along with its Michigan and California facilities run Oracle. The subsidiary

offices will consolidate under the New York entity. Then this division, along with its peer Mexico plant – as well as the Canada and China plants – will consolidate up into the Global Head Office. Once configured for the US operation, Oracle can easily be replicated for the Mexico plant with

a Spanish language overlay. The roll up of financial data such as the general ledger and sales forecasts can be easily reconciled into the desired currency of the head office and be uploaded.

Oracle is especially well suited to the above scenarios where the satellites are manufacturing facilities. Originally designed to suit the needs of discrete and process manufacturers, Oracle has grown in functionality with features tailored to the needs of a specific facility through codeless configuration – not customization. Oracle is focused specifically on the unique requirements of manufacturing operations and is the only “Manufacturing Cloud” SaaS offering in the ERP market. Through this model, it delivers value quickly with lower implementation and IT support costs.

Moreover, Oracle grows using a “continuous innovation” model where enhancements and upgrades are delivered continuously and does not suffer the obsolescence, or need for upgrade implementations typical of on-premise solutions. In this way, Oracle is uniquely able to stay up to date with the changing needs of manufacturing businesses.

This approach allows Oracle to satisfy the unique requirements of manufacturing operations, such as:

-

Real-time production ecosystem:

Oracle MES delivers a real-time interoperable production system that guides, initiates and reports shop floor activities as they occur for optimized and responsive plant operations & processes.

-

End-to-end traceability

For every action in production, there is a transaction in Oracle so every piece of inventory is tracked for precise genealogy and traceability such as to isolate and contain potential quality issues.

-

Closed-loop quality

Compliance with regulatory and quality standards is delivered through an integral quality control and checkpoint system in Oracle MES, minimizing waste and ensuring standards compliance, documentation and traceability needs.Oracle customers are often large multi-national corporations and require systems targeted to streamline and grow their operations.

WHY ORACLE NOW

Built from the ground up for the cloud by manufacturing experts, Oracle delivers the broad and deep ERP functionality that puts you ahead of the competition. The Oracle Manufacturing Cloud is 100% focused on discrete and process manufacturing with industry-leading plant floor to top floor functionality. ERP from the Oracle Manufacturing Cloud delivers unprecedented customer success through a relentless pursuit of continuous innovation for the manufacturing industry. The reason to choose Oracle can be summed up by:

Built for manufacturers.

With the resurgence of manufacturing following the Great Recession, manufacturers are faced with challenges to keep up with growing capacity. Because it was designed specifically for manufacturers, Oracle more directly addresses the problems that modern manufacturers face. Oracle allows you to drive operational efficiency by improving inventory accuracy, product quality and real-time reporting/analytics.

Visibility of Operations.

As a complete, end-to-end solution for manufacturing businesses, Oracle delivers a single, centrally managed source of manufacturing and business data. Connected from the top floor (business) all the way to workcenters on the plant floor and all the way to the shop-floor equipment itself, Oracle ensures that data is collected at the “manufacturing moment.” This visibility makes traceability to specific data quick and easy and makes it simple to report and share across the enterprise.

Cloud Adoption

The rapid increase in companies adopting cloud technologies – especially in controlled ways such as functional or division level – makes deploying Oracle at a plant level a viable strategy. The lower IT overhead costs make spinning up a new plant easier and more cost effective with lower risk. Moreover, replicating a successful deployment to additional plants can be accomplished in weeks versus months.

About ERTechnologies as your Cloud Partner?

ERTechnologies is the leading Oracle partner delivering The Oracle Manufacturing Cloud for manufacturers. ERT has pioneered cloud solutions for the shop floor, connecting suppliers, machines, people, systems, and customers with capabilities that are easy to configure, deliver continuous innovation, and reduce IT costs. With insight that starts on the production floor, we help manufacturers see, understand and uncover the value hidden in their Oracle technology investments by capturing unexpected opportunities to fuel growth and profitability in every aspect of their business ecosystems, enabling them to lead in ever-changing markets using Oracle technologies.

Learn more at www.ER-Technologies.com | 949.387.0250

What is Two-Tier ERP and How Does It Work?

As a company expands, whether organically or through mergers and acquisitions, the benefits of a unified view into financial systems don’t diminish. If anything, it becomes more critical. But trying to extend a primary enterprise resource planning (ERP) system to encompass diverse business units or subsidiaries that may have entirely different reporting and compliance structures is a sure way to get mired in complexity.

Instead, look at your organizational chart for inspiration, and think in layers.

What is Two-Tier ERP?

Two-tier ERP is an approach to enterprise resource planning technology that uses two systems to address the needs of large businesses with multiple locations and/or subsidiaries. Under this strategy, headquarters will use a Tier 1 ERP that’s highly customized and has the functionality to run a large, global company, while subsidiaries or smaller business units use a less resource-intensive Tier 2 ERP that better suits their needs.

With two-tier ERP, the business integrates the two ERP systems so information automatically flows from Tier 2 to Tier 1. This allows for master data management, or a single source of accurate data for the entire enterprise. Although the responsibilities of each system can vary, the Tier 1 software often handles core business functions like finance, human resources and procurement. The Tier 2 system manages activities, like sales, marketing or manufacturing processes, that are more specific to each subsidiary or location.

This ERP strategy became popular as vendors developed less expensive suites with more prebuilt functionality as alternatives to legacy ERP systems that burdened companies with long, expensive, and usually on-premises implementations and extensive configuration requirements. Many companies realized a two-tier approach was far more economical and less work than replacing the Tier 1 ERP or moving a new subsidiary or acquired company onto its enterprise software.

Tier 1 vs. Tier 2 ERP

There are two distinct categories of ERP systems with different capabilities, each designed for businesses of a certain size.

Tier 1

A Tier 1 ERP is built for the world’s largest businesses that have operations around the globe. These systems are very expensive to install, maintain and upgrade. Customizing them to meet the business’ vast requirements takes a lot of effort, which leads to long implementation times. Companies typically have an IT team dedicated to managing this software.

Tier 2

A Tier 2 ERP is designed for midsize companies and small enterprises. This type of ERP is usually much less expensive and easier to launch than Tier 1 software. Some solutions in this category target specific industries, like manufacturing or retail, and come with more out-of-the-box functionality for accounting, sales, human resources and supply chain (including order and inventory management). One software vendor could offer both Tier 1 and Tier 2 ERP solutions.

Let’s look at big-picture business advantages of a layered model then dig into more tactical benefits.

Two-Tier ERP Advantages

Two-tier ERP has become a popular approach for enterprises that want a powerful system at the corporate level but need a complementary solution for subsidiaries or international locations.

On a strategic level, when a company is acquired, any effort to impose a monolithic Tier 1 ERP system is likely to cause disruption—the last thing an acquirer wants. If the goal is to help the subsidiary run better and more profitably, the advantages of a lighter weight, more customizable Tier 2 system become clear. For the parent company, there’s no compromise in terms of gaining access to data, and the IT team avoids the headache of linking (possibly very) disparate ERPs.

Don’t assume that a subsidiary won’t want to invest in training its employees on a Tier 2 ERP. In fact, in Brainyard’s Summer 2020 Survey, new training was high on the priorities list for 57% of finance execs.

Learn more

That’s not to say there won’t be any disruption. Perhaps the subsidiary is using a very basic system that can’t integrate with the parent company’s Tier 1 ERP, or maybe there’s no modern financial software in place at all. In that case, the IT team or integration partner would do well to sell the subsidiary on the nuts-and-bolts benefits of having its own ERP.

Benefits of Two-Tier ERP

On the ground, the benefits of a two-tier strategy include:

▪ Cost savings: This is perhaps the most appealing aspect of two-tier ERP, especially for companies facing other costs involved in M&A activity. Implementation, maintenance and upgrade costs tend to be reasonable, particularly if the parent company has standardized multiple subsidiaries on the same Tier 2 system. Further, since the Tier 2 system requires less attention and can share IT resources with the corporate office, the company could eliminate

some IT headcount, especially due to redundant positions, or redirect that talent toward projects that benefit the business more directly.

▪ Meet specific business needs: A business unit within an enterprise may have software requirements different from those of the primary business because of what it sells or the industry it serves. A specialized ERP tailored to the smaller business’ needs will simply work better for finance and could drive efficiencies it wouldn’t realize with the Tier 1 system.

▪ Greater flexibility and control: Since a Tier 2 ERP is less complex and “lighter,” it’s faster and easier to adjust the software as necessary. This empowers these smaller segments of a large corporation to respond to changes in the market or shifts in customer behavior in a timelier manner. It also gives these units more control over their operations and processes.

▪ Address local requirements: A subsidiary in a different country may need a system that uses a different currency or language and must comply with local laws. There could be subtle cultural or regional disparities that affect how this office operates. A Tier 2 ERP can accommodate all of those special considerations if they are not included in the Tier 1 system.

▪ Better user experience: Tier 1 systems are often difficult to use and have an intimidating learning curve. A Tier 2 ERP is more likely to have a user-friendly interface and a better overall user experience. This could also cut down on training costs.

Two-Tier ERP Use Cases

Through many failed projects and blown budgets, large businesses have learned it often doesn’t make sense to migrate an acquired company or new subsidiary onto a Tier 1 ERP.

Let’s break down a few use cases where a two-tier ERP strategy makes sense:

▪ Subsidiaries that have a business model distinct from the larger company. For example, the main office sells computer hardware and software while the subsidiary focuses on IT services and consulting.

▪ Subsidiaries that sell into a different industry than the larger enterprise or serve a niche market. This could require certain features that the Tier 1 ERP doesn’t have. ▪ Business units or offices that operate out of a different country than headquarters. The Tier 2 ERP can not only use the local language and currency but be configured to follow that country’s tax laws and other regulations.

▪ Organizations that become part of another corporation through a merger or acquisition. Bringing another business’ processes and operations onto an existing ERP can be extremely time- and cost-intensive, so giving the organization a dedicated platform is often a better choice.

▪ An acquired company that doesn’t have a formal business management system or uses basic, introductory software.

▪ A company that wants to take advantage of the features and user-friendliness of a newer solution while still utilizing its legacy ERP for certain business functions or processes. This is a much faster and simpler alternative to replacing the main ERP, which could be a massive project.

Choosing an ERP System for a Two-Tier Strategy

First and foremost, companies need to find a Tier 2 ERP that will easily integrate with the Tier 1 system to enable master data management. This will ensure there is always a central, accurate source of information and prevent manual data entry and endless headaches.

The complementary system should also support standard back- and front-office functions, like accounting, supply chain, sales, marketing and operations, along with specialized needs at the company. It should display real-time data and have powerful reporting capabilities. For international locations, support for multi-currency and multi language is essential. The Tier 2 software should be adaptable so it can not only meet the needs of but evolve with a specific business model or industry. Look for a modular setup.

Additionally, the initial cost and total cost of ownership (TCO) for a Tier 2 ERP should not be onerous. That’s part of the reason why many enterprises choose a SaaS ERP, as it’s faster to implement and requires minimal maintenance since the vendor hosts the solution on its own infrastructure and handles all upgrades and patches. SaaS ERP appeals to companies that already have to dedicate a lot of human and capital resources to keeping their Tier 1 ERP running smoothly and would prefer a turnkey option for remote sites.

When it comes to selecting a Tier 2 ERP, corporations can:

▪ Let a subsidiary or international location complete its own evaluation process and select any vendor. However, what analysts calls the “laissez-faire” approach could lead to integration issues with the Tier 1 system.

▪ Give the business unit a list of approved solutions or software providers. These could be systems the main office vetted and knows will play well with its enterprise software—preferably with prebuilt integrations—or Tier 2 solutions offered by the Tier 1 ERP vendor.

About ERTechnologies as your Cloud Partner?

ERTechnologies is the leading Oracle partner delivering The Oracle Manufacturing Cloud for manufacturers. ERT has pioneered cloud solutions for the shop floor, connecting suppliers, machines, people, systems, and customers with capabilities that are easy to configure, deliver continuous innovation, and reduce IT costs. With insight that starts on the production floor, we help manufacturers see, understand and uncover the value hidden in their Oracle technology investments by capturing unexpected opportunities to fuel growth and profitability in every aspect of their business ecosystems, enabling them to lead in ever-changing markets using Oracle technologies.

Learn more at www.ER-Technologies.com | 949.387.0250